counter button for event

the company i worked for designed and produced over 25 makeup brand booths at a convention and one of them decided they wanted a button for people to press as they enter the booth and a number on a screen would increment.

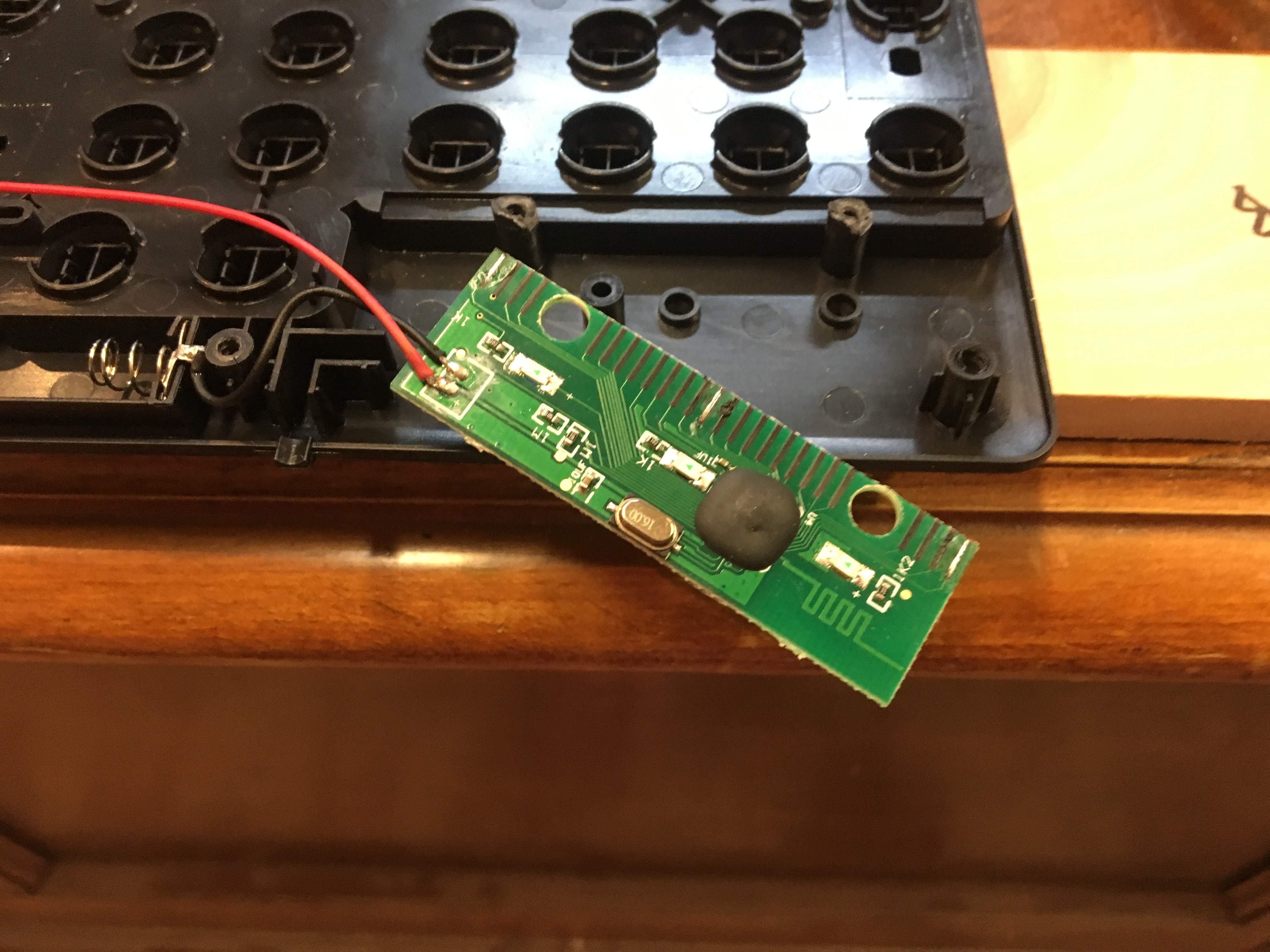

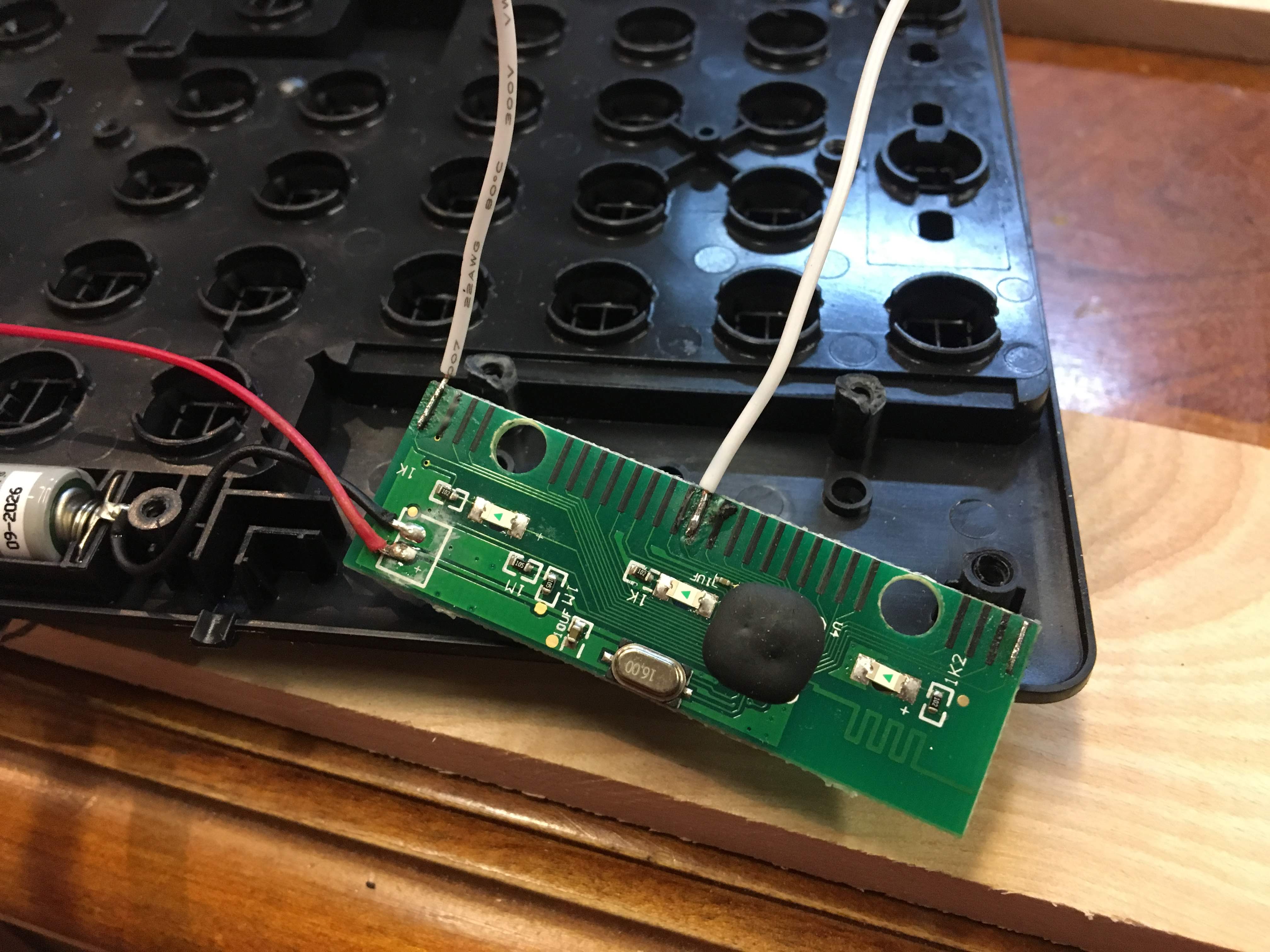

i take on the project having absolutely no experience coding and started by hacking apart a cheap bluetooth keyboard. i knew that, in theory, i needed a receiver otherwise we'd have an ugly, 15' wire to deal with.

i take on the project having absolutely no experience coding and started by hacking apart a cheap bluetooth keyboard. i knew that, in theory, i needed a receiver otherwise we'd have an ugly, 15' wire to deal with.

being in the event industry - you look for items that are already built and salvage them for parts. it's much faster this way.

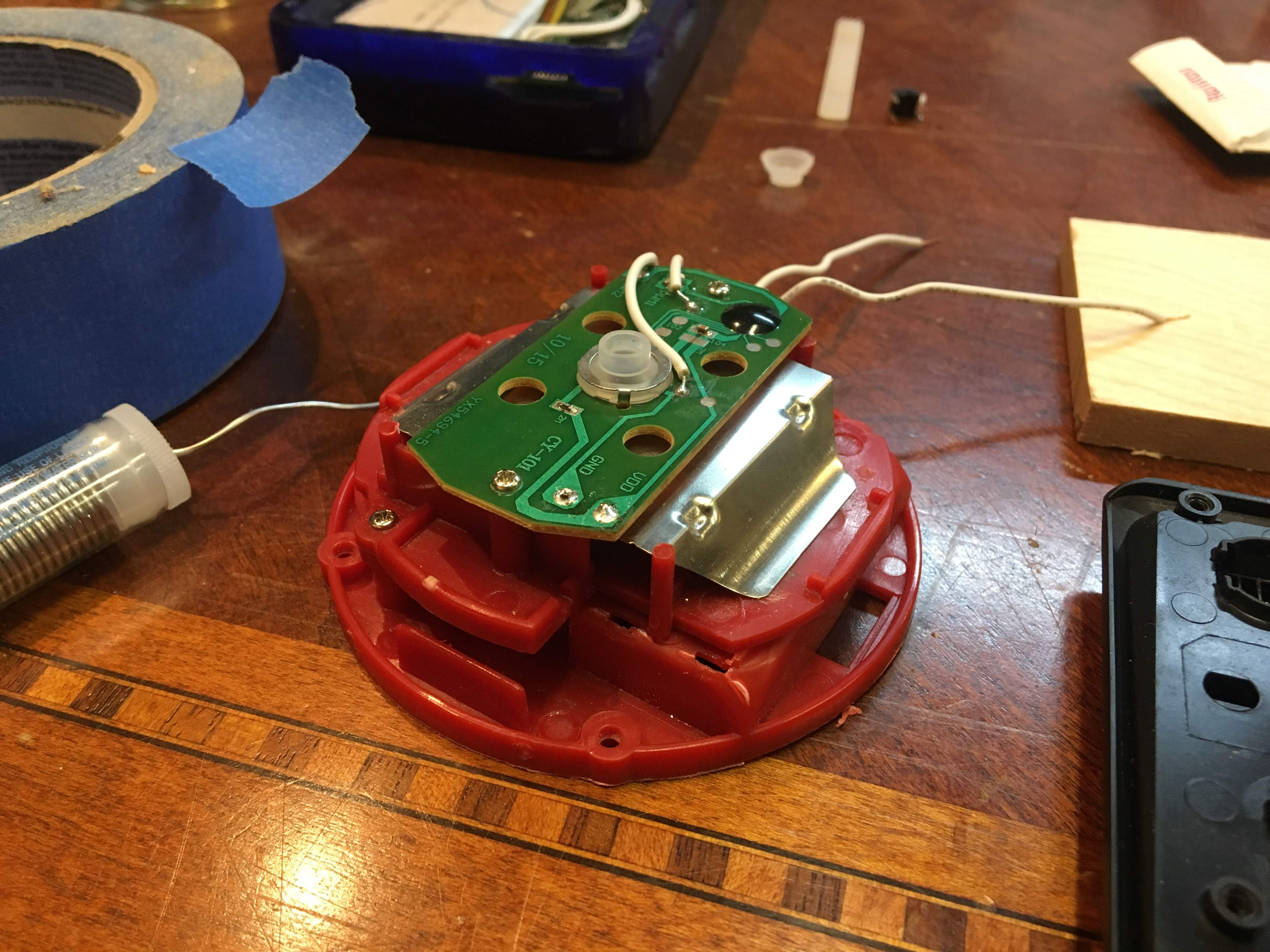

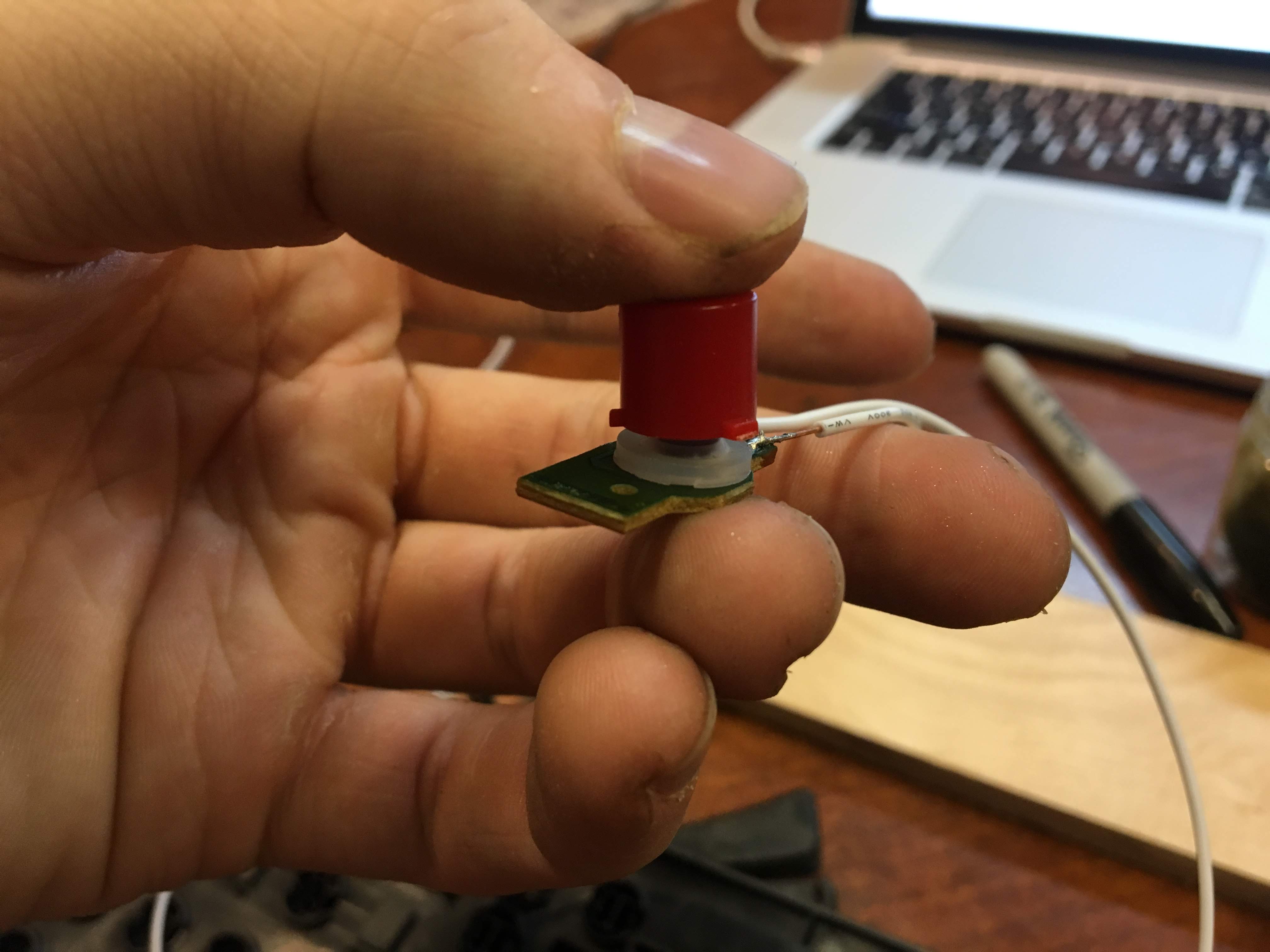

in this case, i took a staples easy button because of it's size, shape, and function and put my new circuit inside of it.

in this case, i took a staples easy button because of it's size, shape, and function and put my new circuit inside of it.

inspecting the circuit in the cheap bluetooth keyboard i quickly realized that every key on the keyboard was actually connected by the same, partially broken, conductive trace.

because of this, i devised a theory that maybe the logic of the board is set to read different resistances as different keys on the board.

to my suprise, that's exactly what was going on and by carfully soldering some leads on the board, i was able to print out '000000' on screen.

because of this, i devised a theory that maybe the logic of the board is set to read different resistances as different keys on the board.

to my suprise, that's exactly what was going on and by carfully soldering some leads on the board, i was able to print out '000000' on screen.

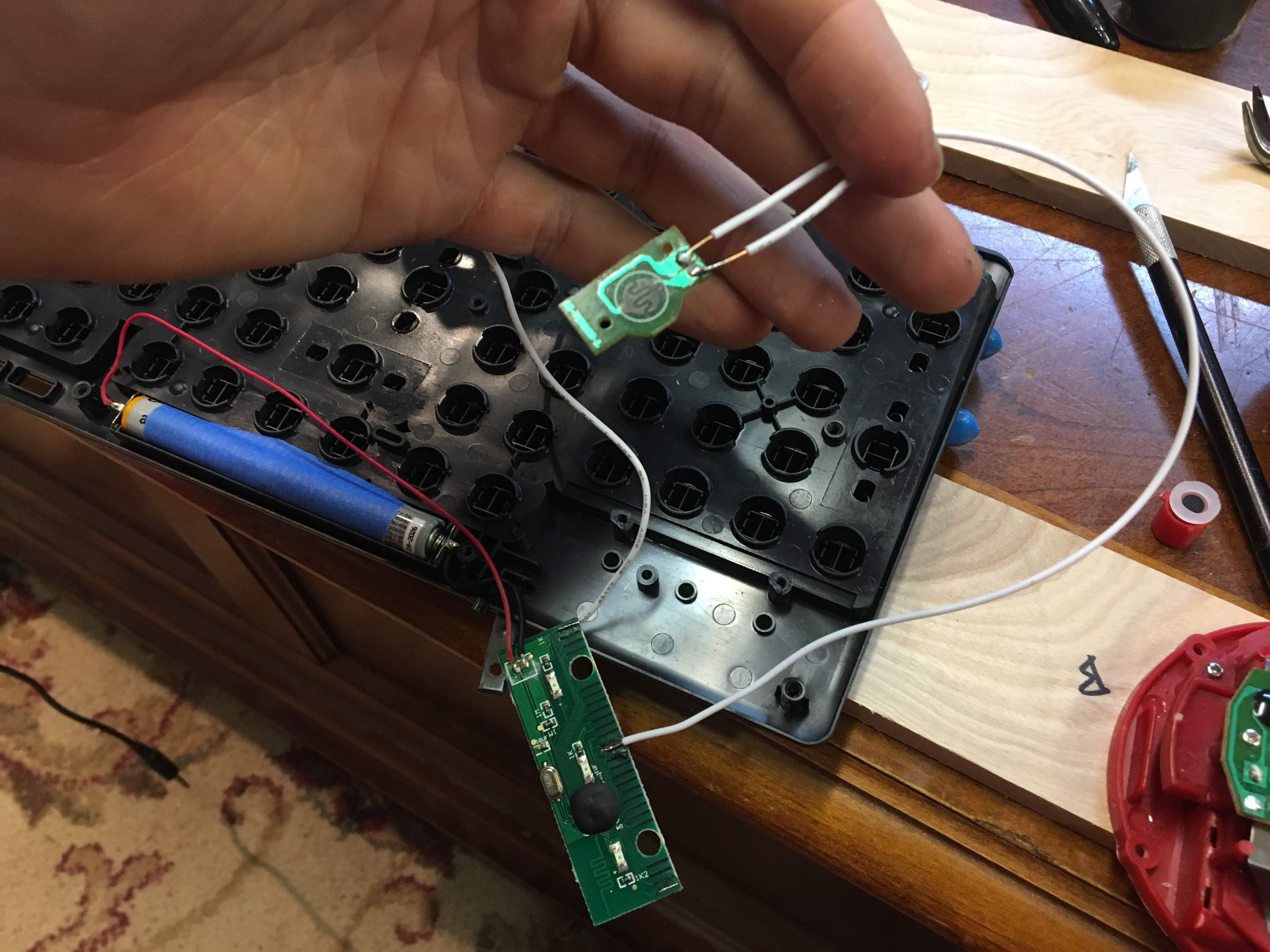

i could rely on two loose wires touching each other when someone hits the button - so i further salvage a conductive pad and trace from an old usb game controller.

this was a really useful step because the button cap was so tall, i could slowly sand it down to adjust for the throw of the button. that way i could guarantee the button press would work every time.

this was a really useful step because the button cap was so tall, i could slowly sand it down to adjust for the throw of the button. that way i could guarantee the button press would work every time.